-

Industrial Boiler

1500 Kg – 1.5 Ton FO Fired Package Steam Boiler, IBR Approved

₹1,475,000.00 Add to cart -

Industrial Boiler

2 Ton ( 2000 kg/hr ) Oil Fired Steam Boiler, Automatic Industrial Steam Generator

₹1,750,000.00 Add to cart -

Industrial Boiler

500 Kg LDO Fired Steam Boiler – Industrial Grade Oil-Fired System

₹915,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Gas Fired Steam Boiler (PNG / LPG Compatible)

₹3,250,000.00 Add to cart -

Industrial Boiler

6000 Kg – 6 Ton Diesel Fired Steam Boiler – Industrial Steam Generator

₹3,750,000.00 Add to cart -

Industrial Boiler

Gas-Fired Industrial Steam Boiler 200 Kg/hr – Natural Gas/LPG

₹490,000.00 Add to cart

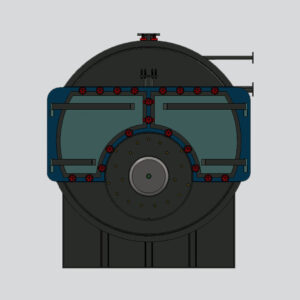

Industrial Dual Fuel Steam Boilers (Oil & Gas Fired)

In today’s volatile energy market, relying on a single fuel source is a risk to your production. Indian Boilers provides advanced Dual Fuel Steam Boilers engineered to switch between gaseous fuels (PNG/LPG) and liquid fuels (Diesel/LDO) with zero hassle. Whether you are facing a gas supply disruption or looking to switch to the most economical fuel of the day, our dual-fuel systems provide the ultimate operational security.

Key Benefits Of Dual Fuel Steam Boilers

- Uninterrupted Production: Never stop your plant due to fuel shortages. Switch from gas to oil or vice versa in minutes.

- Fuel Cost Optimization: Take advantage of market price fluctuations. Burn the cheaper fuel to lower your steam generation cost per ton.

- High Thermal Efficiency: Our 3-pass wet-back design ensures up to 88% efficiency (and up to 95% with an external economizer).

- Advanced Burner Technology: Equipped with world-class modulating dual-fuel burners for precise air-fuel ratio control and low NOx emissions.

- Plug-and-Play Automation: Fully automatic control panels with safety interlocks for flame failure, low water level, and high pressure.

Technical Specifications Table

| Feature | Gaseous Fuels | Liquid Fuels |

| Primary Options | PNG (Natural Gas), LPG | Diesel (HSD), LDO |

| Capacity Range | 0.5 TPH to 10 TPH | 0.5 TPH to 10 TPH |

| Design Pressure | 10.54, 14.5, 17.5 kg/cm² | 10.54, 14.5, 17.5 kg/cm² |

| Efficiency (with HRU) | ~95% | ~92% |

| Standard Compliance | IBR / Non-IBR | IBR / Non-IBR |

Fuel Options Breakdown

- PNG + Diesel: The most popular industrial setup for high-speed automated production.

- LPG + LDO: A cost-effective solution for areas where natural gas pipelines are not yet available.

- Biogas + Oil: Eco-friendly hybrid systems for chemical and agricultural processing plants.

Application Dual Fuel Boiler

Our dual-fuel steam generators are widely used in:

- Chemical & Pharma: For precise temperature control.

- Food & Beverage: Ensuring zero downtime in continuous processing.

- Textiles: For high-volume, reliable steam supply.

- Hotels & Hospitals: For hot water and sterilization requirements.