-

Industrial Boiler

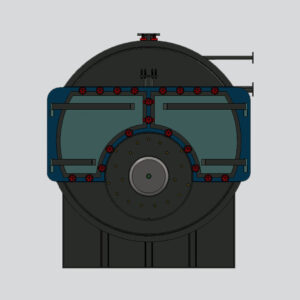

1000 Kg – 1 Ton Horizontal Fire Tube Boiler (Wood Log Fuel)

₹1,553,000.00 Add to cart -

Industrial Boiler

1500 Kg – 1.5 Ton FO Fired Package Steam Boiler, IBR Approved

₹1,475,000.00 Add to cart -

Industrial Boiler

1500 Kg – 1.5 Ton Steam Boiler (Groundnut Fired) – Biomass Industrial

₹1,650,000.00 Add to cart -

Industrial Boiler

2 Ton ( 2000 kg/hr ) Oil Fired Steam Boiler, Automatic Industrial Steam Generator

₹1,750,000.00 Add to cart -

Industrial Boiler

2000 Kg – 2 Ton Wood Pellet Fired Fire Tube Steam Boiler

₹2,660,000.00 Add to cart -

Industrial Boiler

3000 Kg – 3 Ton Bagasse Fired Boiler – Automatic Biomass Steam Generator

₹3,150,000.00 Add to cart -

Industrial Boiler

500 Kg LDO Fired Steam Boiler – Industrial Grade Oil-Fired System

₹915,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Coal Fired Steam Boiler – Industrial Horizontal Steam Generator

₹5,000,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Gas Fired Steam Boiler (PNG / LPG Compatible)

₹3,250,000.00 Add to cart -

Industrial Boiler

6000 Kg – 6 Ton Diesel Fired Steam Boiler – Industrial Steam Generator

₹3,750,000.00 Add to cart -

Industrial Boiler

Gas-Fired Industrial Steam Boiler 200 Kg/hr – Natural Gas/LPG

₹490,000.00 Add to cart -

Industrial Boiler

High Pressure Industrial Steam Boiler 750 Kg/hr – Heavy Duty Boiler

₹1,380,000.00 Add to cart

Industrial Steam Boilers: High-Pressure Reliability

Precision-Engineered Steam Solutions for Maximum Operational Uptime

At indianboilers.com, we understand that an Industrial Steam Boiler is more than just a piece of equipment—it is the lifeline of your production process. Our steam boilers are designed to deliver consistent, high-quality dry steam while maintaining the lowest possible fuel consumption.

Whether you require a Fire Tube Boiler for stable, high-volume steam or a Water Tube Boiler for rapid response and high pressure, our 2026 range offers the latest in thermal technology and safety automation.

Types of Industrial Steam Boilers We Offer

Fire Tube Steam Boilers (Shell Type)

Ideal for small to medium industries where load demand varies.

- Best for: Food processing, Breweries, and Laundry units.

- Advantage: Simple to operate, large water storage for stable steam pressure, and easier maintenance.

Water Tube Steam Boilers (Coil Type)

The “Instant Steam” solution for high-pressure industrial applications.

- Best for: Power plants, Chemical refineries, and Pharmaceuticals.

- Advantage: Rapid startup (3–5 minutes), compact footprint, and safely handles pressures exceeding 21 kg/cm2.

Electric Steam Boilers

A zero-emission, silent alternative for urban or cleanroom environments.

- Best for: Hospitals, laboratories, and high-tech manufacturing.

- Advantage: No chimney required, 98% efficiency, and fully automated touch-screen controls.

Key Features & Competitive Advantages

- 92% Thermal Efficiency: Equipped with advanced Economizers and Air Preheaters that recover waste heat from flue gases to preheat feedwater.

- Fuel Versatility: Our burners are compatible with Natural Gas, LPG, Diesel (HSD), Wood, and Biomass Briquettes.

- Dry Steam Quality: Integrated internal moisture separators ensure a dryness fraction of 0.98 or higher, protecting your downstream equipment from water hammer.

- IBR Compliance: Every boiler is manufactured strictly as per Indian Boiler Regulations (IBR), ensuring peak safety and seamless legal documentation.

- Modular Design: Compact vertical and horizontal models designed to fit into existing boiler houses with minimal civil work.

Uncompromising Safety Mechanisms

Safety is our top priority. Every IndianBoilers.com is fitted with:

- Dual Safety Valves: To automatically relieve excess pressure.

- Low Water Cut-Off (LWCO): Shuts down the burner instantly if water levels drop to unsafe levels.

- Flame Failure Detection: Prevents fuel accumulation in the furnace to avoid explosions.

- Automatic Blowdown System: Removes dissolved solids to prevent scale buildup and tube overheating.

Trusted Across Global Industries

Headquartered in the industrial heart of Ahmedabad, we are strategically positioned to serve India’s most demanding sectors. From the local GIDC hubs of Gujarat to the Pharma giants in Baddi, our steam boilers are the backbone of:

- Textiles: Powering Ahmedabad’s legacy and Surat’s modern hubs with steam for dyeing, finishing, and high-speed processing.

- Pharmaceuticals: Meeting the stringent “Clean Steam” standards for sterilization and autoclaving in Baddi, Sikkim, and Ahmedabad’s pharma clusters.

- Food & Dairy: Ensuring hygiene and efficiency for pasteurization, sterilization, and large-scale industrial cooking.

- Plywood & Laminates: Delivering the consistent high pressure and temperature required for critical hot-press cycles.

- Chemicals & Agrochemicals: Providing precise temperature control for complex reactor vessels in the Dahej and Ankleshwar belts.

Talk To IndiaBoilers.com Experts

Don’t let inefficient steam generation drain your profits. Contact indianboilers.com for a customized fuel-saving audit and a quote tailored to your TPH (Tonnes Per Hour) requirements.

Frequently Asked Questions

Are your boilers IBR (Indian Boiler Regulations) compliant?

Yes, all our industrial boilers are manufactured strictly according to IBR standards, ensuring legal safety compliance and seamless documentation for your facility.

What is the difference between your Fire Tube and Water Tube boilers?

Our Fire Tube boilers are ideal for stable, high-volume steam (best for food/laundry), while our Water Tube/Coil type boilers offer "instant steam" (3–5 minute startup) for high-pressure needs.

Do you provide Non-IBR boilers?

Yes, we manufacture high-efficiency Non-IBR boilers for small industrial applications where regulatory requirements are less stringent, typically for capacities below certain thresholds.

Where is your manufacturing facility located?

Our main manufacturing plant is located in Vatva GIDC, Ahmedabad, Gujarat, which allows us to serve industrial hubs across India effectively.

What fuels can your industrial boilers run on?

Our boilers are highly versatile. We offer models fired by Natural Gas, PNG, LPG, Diesel (HSD), LDO, Furnace Oil (FO), and solid fuels like Wood logs, Coal, Bagasse, Groundnut shells, and Wood pellets.

What is the thermal efficiency of an Indian Boilers unit?

Most of our industrial boilers achieve up to 92%–95% thermal efficiency when equipped with our advanced sensible heat recovery units and economizers.

Can I switch fuel types later, such as moving from Diesel to PNG?

Yes, many of our units can be fitted with dual-fuel burners or have their burners replaced to switch between liquid and gaseous fuels as market prices fluctuate.

How do you ensure dry steam quality?

Every boiler features integrated internal moisture separators that ensure a dryness fraction of 0.98 or higher, protecting your process equipment from water hammer.

Do you offer biomass-fired boilers to reduce carbon footprint?

Absolutely. We have specific models designed for wood pellets, groundnut shells, and bagasse to help industries meet sustainability goals.

What is the capacity range of your industrial boilers?

Our standard range starts from 300 Kg/hr (small units) up to 10 Ton per hour (TPH) for large-scale industrial plants.

What working pressures do your boilers support?

Our standard designs operate between 10.54 kg/cm² and 17.5 kg/cm², with high-pressure custom models available up to 21 kg/cm² and above.

What does "Skid-Mounted" mean for your products?

It means the boiler, feed pump, and control panel are integrated onto a single steel frame. This "Plug-and-Play" design allows for rapid installation with minimal civil work.

How long does it take to generate steam from a cold start?

Our Coil-type (Water Tube) boilers can generate full steam within 3 to 5 minutes, while larger Shell-type boilers take longer but provide more stable pressure for large surges.

What safety features are included in your boilers?

Every unit is equipped with dual safety valves, a Low Water Cut-Off (LWCO) system, flame failure detection, and an automatic blowdown system for scale prevention.

How often does an industrial boiler require maintenance?

We recommend a basic monthly check and a comprehensive annual inspection. Our hinged smoke chamber design makes tube cleaning and inspection very easy.

Do you provide on-site installation and commissioning?

Yes, our engineering team handles the complete installation, commissioning, and operator training to ensure your team can run the boiler safely and efficiently.

Are spare parts easily available?

Since we manufacture in Ahmedabad and use global standard components (like ELCO burners), we maintain a full inventory of spares for immediate dispatch.

Which industries are your 1 Ton and 2 Ton boilers best suited for?

These capacities are the "workhorses" for the Textile, Pharmaceutical, Food & Dairy, and Chemical industries in hubs like Surat, Baddi, and Ankleshwar.

How do I choose the right TPH (Ton Per Hour) capacity for my plant?

Our experts can perform a fuel-saving audit and steam load calculation for your facility to determine the exact capacity needed to avoid under-performance or energy waste.