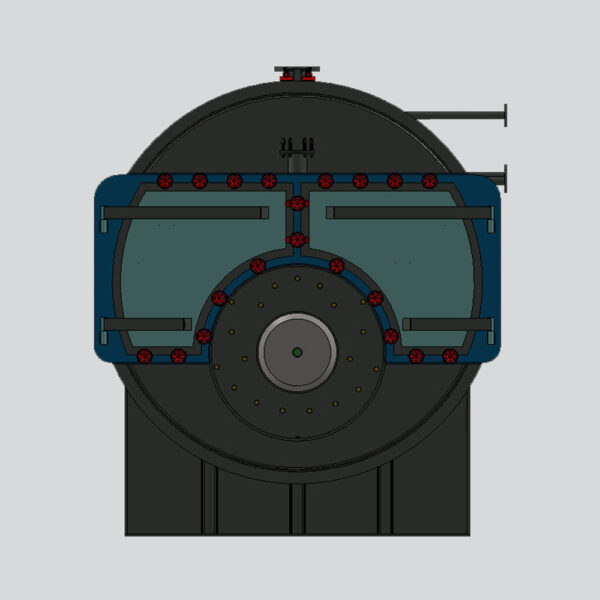

1.5 Ton FO Fired Steam Boiler (1500 Kg/hr)

Heavy-Duty Steam | High Viscosity Fuel Efficiency | German Combustion Tech

At IndianBoilers.com, our 1.5 Ton FO (Furnace Oil) Fired Steam Boilers are built for industries that require high-volume steam using economical heavy oils. Using specialized heating and pumping systems to handle the higher viscosity of Furnace Oil, this boiler delivers reliable, continuous steam for the most demanding manufacturing environments.

Manufactured at our Ahmedabad plant, our STEAMJET SJ-15 series is 100% skid-mounted, ensuring a robust, space-saving solution that is ready for immediate integration into your production line.

Key Features & Performance

- 95% Maximum Efficiency: Achieve peak thermal performance of up to 95% when paired with our advanced sensible heat recovery units.

- FO-Specific Burner System: Equipped with specialized steam-atomized or dual-block burners from ELCO-Germany to ensure complete combustion of heavy oils.

- High Dryness Fraction: Delivers steam with a high dryness fraction, significantly increasing the usable heat available for your industrial processes.

- Plug-and-Play Skid Mounting: The entire 1.5 TPH unit is 100% skid-mounted, allowing for rapid onsite installation and minimal civil work.

- Fluctuation Management: Features a large water-holding capacity, allowing the boiler to handle sudden steam load surges without pressure drops.

- Intelligent Monitoring: Includes advanced control panels and optional 3-element systems for real-time tracking of water level, steam flow, and feedwater flow.

- Multi-Fuel Flexibility: While optimized for FO, the system also supports light oils and gases, providing long-term fuel security.

Operating Range

Our 1.5 Ton FO series is engineered for high-uptime industrial reliability.

- 1. Capacity: 1.5 Ton (1500 Kg/hr) — Part of our range from 0.5 TPH to 10 TPH.

- 2. Fuel Compatibility: Furnace Oil (FO), LSHS, LDO, HSD, and Natural Gas.

- 3. Working Pressure: Precision designs for pressures between 10.54 $Kg/cm^2$ and 21 $Kg/cm^2$.

- 4. Safety Standards: Fully IBR (Indian Boiler Regulations) compliant for legal safety and structural integrity.

Core Industry Applications

The 1.5 Ton FO Boiler is a workhorse for:

- Chemical & Fertilizers: Reliable steam for large-scale reaction vessels.

- Asphalt & Road Construction: Constant heating for bitumen and raw materials.

- Textile Processing: High-pressure steam for bleaching, dyeing, and drying.

- Rubber & Plastics: Uniform heat for vulcanization and molding processes.

Advantages

By choosing IndianBoilers.com, you benefit from Ahmedabad’s premier engineering expertise:

- Low Stack Temperatures: Our design captures maximum heat, resulting in low stack temperatures at the boiler outlet and reduced fuel waste.

- Ease of Maintenance: Features a hinged smoke chamber that simplifies tube cleaning and facilitates ash settling.

- Local Support: Based in Ahmedabad, we offer rapid delivery of spares and 24/7 technical assistance for IBR documentation and burner tuning.

Technical Specifications

| Specification | Unit | SJ-05 | SJ-10 | SJ-15 | SJ-20 | SJ-30 | SJ-40 | SJ-50 | SJ-60 | SJ-80 | SJ-100 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| General | |||||||||||

| Steam Output From & at 100°C | Kg/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Working Pressure | Kg/CM² | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 | 10.54 |

| Steam Temprature | °C | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 183 | 184 | 185 |

| No’s Passes | No’s | Three | Three | Three | Three | Three | Three | Three | Three | Three | Three |

| No’s of Furnace | No’s | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Steam Outlet | MM | 40 | 50 | 80 | 80 | 100 | 100 | 125 | 150 | 150 | 200 |

| HTA | M² | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 180 | 240 | 300 |

| Burner: Pressure jet Monoblock Burner | |||||||||||

| Type of Fuel: Diesel, LPG, NG, PNG, FO, LDO | |||||||||||

| Boilers Efficiency | |||||||||||

| On Gas | % | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 | 90 +/-2 |

| On Oil | % | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 | 88 +/-2 |

| Fuel Consumption | |||||||||||

| Diesel (10500) | Kg/hr | 29 | 58 | 88 | 117 | 175 | 234 | 292 | 351 | 468 | 584 |

| Furnace Oil (9600) | Kg/hr | 32 | 64 | 96 | 128 | 192 | 256 | 320 | 384 | 511 | 639 |

| LDO (10200) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| LPG (11000) | Kg/hr | 30 | 60 | 90 | 120 | 180 | 241 | 301 | 361 | 481 | 602 |

| Natural gas(8900) | M³/hr | 34 | 67 | 101 | 135 | 202 | 270 | 337 | 404 | 539 | 674 |

| Electrical Load | |||||||||||

| Feed Water Pump | H.P. | 2.00 | 2.00 | 3.00 | 3.00 | 4.00 | 4.00 | 6.00 | 7.50 | 10.00 | 15.00 |

| Burner Blower (oil) | H.P. | 0.37 | 1.10 | 3.00 | 3.00 | 5.50 | 7.50 | 7.50 | 11.00 | 18.5 | 18.5 |

| Fuel Pump | H.P. | * | * | * | * | 1.10 | 1.10 | 1.10 | 1.50 | 3.0 | 3.0 |

| Total Electric Load | H.P. | 2.37 | 3.10 | 6.00 | 6.00 | 10.60 | 12.60 | 14.60 | 20.00 | 31.50 | 36.50 |

| NOTE: In view of constant endeavors to improve our products, we reserve the right to alter or change above specifications without prior notice. | |||||||||||

Frequently Asked Questions

Why should I choose Furnace Oil (FO) over Diesel (HSD)?

Furnace Oil is a heavy fuel that is significantly more cost-effective for large-scale steam production than Diesel, making it ideal for high-uptime industrial processes.

Does this boiler require a fuel pre-heater?

Yes. Because Furnace Oil is highly viscous at room temperature, our 1.5 Ton unit includes an integrated outflow heater/pre-heater to thin the oil for proper atomization.

What is the thermal efficiency of this FO-fired model?

Our FO fired boilers achieve up to 88% efficiency, which can be boosted to 95% with the addition of a sensible heat recovery unit (Economizer).

Can this boiler handle "dirty" or high-viscosity fuels?

Yes, the system is equipped with heavy-duty filters and steam-atomized burners specifically designed to handle the impurities and density of industrial furnace oil.

What is the exact steam output?

The rated capacity is 1500 Kg/hr (1.5 TPH) of high-quality dry steam.

What burner brand is used in the 1.5 TPH model?

We equip this model with world-renowned ELCO-Germany or equivalent high-precision dual-block burners for stable combustion.

What is the standard working pressure?

The standard design pressure is 10.54 Kg/cm², with custom high-pressure options available up to 17.5 Kg/cm².

Is this 1.5 Ton model IBR or Non-IBR?

This is a fully IBR (Indian Boiler Regulations) compliant boiler, manufactured using IBR-approved SA 515/516 boiler quality steel plates.

What is a "3-Pass Wet Back" design?

It means the fire/flue gases pass through the water three times to maximize heat transfer. The "wet back" design ensures the rear chamber is surrounded by water, eliminating the need for high-maintenance refractory.

Is the operation fully automatic?

Yes, the boiler is equipped with an automatic control panel that manages the burner firing, water level control, and pressure cut-offs without manual intervention.

Does it come with a skid-mounted option?

Yes, the 1.5 Ton FO boiler is 100% skid-mounted. The boiler, feed pump, and pre-heating system are integrated on a single frame for "Plug-and-Play" installation.

What is the 3-element control system?

It is an optional advanced monitoring system that synchronizes water level, steam flow, and feedwater flow for maximum safety and efficiency in high-demand plants.

How long does it take to reach full pressure from a cold start?

Typically, it takes 30 to 45 minutes to reach optimum working pressure from a cold state.

What electrical power is required for the 1.5 TPH unit?

The system requires a 3-phase, 415V supply. The total connected load is approximately 5 HP to 7.5 HP including the burner and pump.

How do I clean the smoke tubes?

The boiler features a hinged front door, allowing your operators to easily brush out the smoke tubes during routine maintenance without dismantling the unit.

What safety valves are included?

We provide two IBR-certified spring-loaded safety valves, a low-water alarm, and an automatic flame failure cut-off.

How often should I perform a blowdown?

To prevent scale buildup from FO impurities and water minerals, a manual or automatic blowdown should be performed once per shift (every 8 hours).

What is the expected lifespan of this boiler?

With proper water treatment and regular maintenance, an Indian Boilers 1.5 Ton FO unit has an industrial lifespan of 20+ years.

Does Indian Boilers provide annual maintenance (AMC)?

Yes, our Ahmedabad team offers comprehensive AMCs, including IBR renewal assistance and burner tuning to ensure you get the best fuel economy year-round.

Reviews

There are no reviews yet.