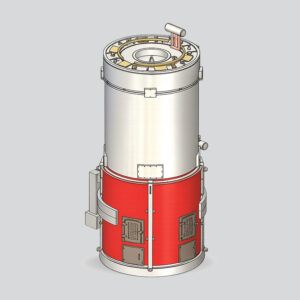

IBR Certified Steam Boilers: Engineered for Safety & Legal Compliance

At IndianBoilers.com, we specialize in the design and manufacturing of boilers that strictly adhere to the Indian Boiler Regulations (IBR), 1950. An IBR boiler is not just a piece of equipment; it is a guarantee of safety, quality, and nationwide legal approval for high-pressure industrial operations.

Whether you are in Textiles, Pharmaceuticals, Chemicals, or Food Processing, our IBR-certified boilers ensure that your facility operates without the risk of legal penalties or safety compromises.

What is an IBR Boiler?

According to the Indian Boilers Act, any vessel with a water capacity exceeding 25 liters used for generating steam under pressure is classified as a “Boiler” and must comply with IBR standards. Compliance involves rigorous inspection of materials (SA 515/516 Gr. 70), design appraisal, and welder qualification by certified government authorities.

Key Features & Performance

- Uncompromising Safety: Every unit undergoes 3-stage inspections (Design, Material, and Hydro-test) by IBR authorities before dispatch.

- High-Grade Metallurgy: We use only IBR-certified seamless tubes and boiler-quality plates to withstand extreme thermal stresses.

- Thermal Efficiency: Optimized 3-pass wet-back designs that achieve 85% to 88% efficiency with heat recovery units.

- Dual Safety Systems: Equipped with IBR-approved dual safety valves, Mobrey water level controllers, and fusible plugs for fail-safe operation.

- Precision Welding: Fabricated by IBR-qualified welders using specialized fusion welding techniques to ensure leak-proof performance.

Technical Specifications

| Specification | Standard Range (IBR Models) |

|---|---|

| Capacity Range | 1.0 TPH to 25.0 TPH |

| Working Pressure | 10.54 kg/cm² up to 32 kg/cm² |

| Fuel Compatibility | Electric, Wood, Briquettes, Coal, Agro-Waste, Gas, and Oil |

| Design Standard | IBR 1950 (Latest Amendments) |

| Efficiency | Up to 88% (with Economizer/APH) |

Why Choose Our IBR Boilers?

- Legal Ease: Avoid project shutdowns and heavy fines with fully documented Form II, Form III-A, and Form IV certifications.

- Long Service Life: Designed with a higher factor of safety and corrosion-resistant materials, our IBR boilers last 20+ years with standard maintenance.

- Higher Resale Value: IBR-certified boilers hold significantly higher market value compared to non-regulated units.

- Nationwide Acceptance: Valid for operation in any state within India without additional design modifications.

Core Industry Applications

- Chemical & Refineries: Reliable high-pressure steam for jacketed vessels and reactors.

- Textiles & Garments: Consistent dry steam for dyeing, printing, and finishing.

- Food & Dairy: Hygienic steam generation for pasteurization and sterilization.

- Plywood & Laminates: Maintaining the precise temperature and pressure required for hot-press cycles.

Need an IBR Certified Solution?

Contact our engineering team today for a customized quote and technical consultation.