-

Industrial Boiler

1000 Kg – 1 Ton Horizontal Fire Tube Boiler (Wood Log Fuel)

₹1,553,000.00 Add to cart -

Industrial Boiler

1500 Kg – 1.5 Ton Steam Boiler (Groundnut Fired) – Biomass Industrial

₹1,650,000.00 Add to cart -

Industrial Boiler

2000 Kg – 2 Ton Wood Pellet Fired Fire Tube Steam Boiler

₹2,660,000.00 Add to cart -

Industrial Boiler

3000 Kg – 3 Ton Bagasse Fired Boiler – Automatic Biomass Steam Generator

₹3,150,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Coal Fired Steam Boiler – Industrial Horizontal Steam Generator

₹5,000,000.00 Add to cart -

Industrial Boiler

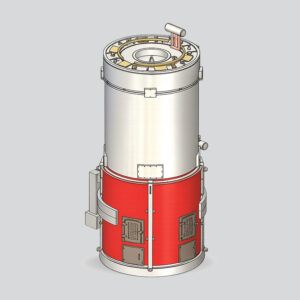

High Pressure Industrial Steam Boiler 750 Kg/hr – Heavy Duty Boiler

₹1,380,000.00 Add to cart

High-Efficiency Groundnut Shell Fired Steam Boilers

At IndianBoilers.com, our Groundnut Shell Fired Steam Boilers are specifically engineered to tap into one of India’s most abundant and high-calorific agricultural residues. Groundnut shells (peanut husks) offer an incredible energy-to-cost ratio, making them the preferred choice for industries looking to switch from expensive fossil fuels to sustainable, carbon-neutral biomass.

Manufactured at our state-of-the-art facility in Ahmedabad, these boilers feature specialized furnace geometries designed to handle the unique combustion properties of groundnut shells, ensuring complete burnout and maximum thermal output.

Key Features & Performance

- Exceptional Fuel Economy: Groundnut shells provide high calorific value (approx. 3800-4200 Kcal/kg), typically reducing operational steam costs by up to 60% compared to LDO or Gas.

- Precision 3-Pass Design: Our smoke-tube technology ensures that flue gases travel through three distinct passes, maximizing heat absorption and achieving thermal efficiency of 82% and above.

- Specialized Grate Systems: Available with stationary or reciprocating grates tailored to manage the light density of groundnut shells while preventing clinker formation.

- Automated Fuel Handling: Equipped with advanced pneumatic or screw-conveyor feeding systems for consistent steam pressure and minimal manual intervention.

- IBR Certified Safety: Every unit is built to Indian Boiler Regulations (IBR) standards using premium-grade steel to ensure a service life of 20+ years.

Technical Specifications

| Specification | Details |

| Capacity Range | 0.5 TPH to 10.0 TPH |

| Working Pressure | 10.54 kg/cm² to 21 kg/cm² (Customizable) |

| Fuel Compatibility | Groundnut Shells, Peanut Husks, Biomass Briquettes, Wood Logs |

| Efficiency | Up to 82% (with Heat Recovery Units) |

| Type | Horizontal 3-Pass Wet-Back / Dry-Back |

| Pollution Control | Multi-cyclone Dust Collector (MDC) / Bag Filter |

Why Choose Our Groundnut Fired Boilers?

- Carbon-Neutral Operation: Help your facility achieve ESG goals by utilizing renewable biomass that releases only the CO2 the plants absorbed during growth.

- Low Maintenance: Designed with large furnace volumes and easy-access manholes to simplify ash removal and tube cleaning.

- Multi-Fuel Flexibility: Our furnaces are versatile; if groundnut shells are seasonally unavailable, you can seamlessly switch to wood chips or briquettes.

- Integrated Heat Recovery: Every boiler can be paired with an Economizer or Air Pre-Heater (APH) to squeeze every bit of energy from the flue gases.

Core Industry Applications

Our groundnut-fired systems are the “Gold Standard” for industries located in major groundnut-producing hubs like Gujarat, Andhra Pradesh, and Tamil Nadu:

- Edible Oil Mills: Use your own byproduct (shells) to generate steam for extraction and refining.

- Food Processing: Reliable, low-cost steam for frying, roasting, and sterilization.

- Textiles & Dyeing: Significant cost reduction for high-volume steam requirements.

- Pharma & Chemical: Precise temperature control for reactors and drying processes.