-

Industrial Boiler

1000 Kg – 1 Ton Horizontal Fire Tube Boiler (Wood Log Fuel)

₹1,553,000.00 Add to cart -

Industrial Boiler

1500 Kg – 1.5 Ton Steam Boiler (Groundnut Fired) – Biomass Industrial

₹1,650,000.00 Add to cart -

Industrial Boiler

2000 Kg – 2 Ton Wood Pellet Fired Fire Tube Steam Boiler

₹2,660,000.00 Add to cart -

Industrial Boiler

3000 Kg – 3 Ton Bagasse Fired Boiler – Automatic Biomass Steam Generator

₹3,150,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Coal Fired Steam Boiler – Industrial Horizontal Steam Generator

₹5,000,000.00 Add to cart -

Industrial Boiler

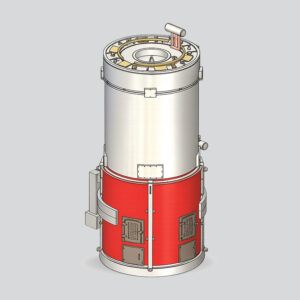

High Pressure Industrial Steam Boiler 750 Kg/hr – Heavy Duty Boiler

₹1,380,000.00 Add to cart

High-Capacity Coal Fired Steam Boilers: Industrial Powerhouse for Reliable Energy

At IndianBoilers.com, our Coal Fired Steam Boilers are engineered to provide a steady, high-volume steam supply for large-scale industrial operations. Designed with a focus on fuel economy and rugged durability, these boilers are the preferred choice for industries where steam demand is high and operational costs must be kept low. Our coal-fired systems feature advanced furnace designs that ensure complete combustion, providing a powerful and cost-effective thermal solution.

Key Features & Performance

- High Thermal Efficiency: Our boilers achieve a thermal efficiency of 82% ± 2% when equipped with external heat recovery units like Economizers or Air Pre-heaters (APH).

- Multi-Fuel Versatility: While optimized for coal, our multi-fuel design allows for the seamless use of Biomass Briquettes, Wood Chips, and Lignite, securing your energy supply against fuel price volatility.

- Robust Grate Technology: Available with specialized Manual Fixed Grates or Automatic Pulsating/Moving Grates to ensure uniform air distribution and effortless ash removal.

- IBR Compliant Safety: Fully manufactured under Indian Boiler Regulations (IBR) using premium SA 515/516 Gr. 70 boiler-quality plates to ensure a service life exceeding 20+ years.

- Advanced Dust Collection: Integrated Multi-cyclone Dust Collectors (MDC) ensure your plant remains compliant with environmental emission norms (GPCB/Pollution Board).

Technical Specifications

| Specification | Details |

| Capacity Range | 1.0 TPH to 50.0 TPH |

| Working Pressure | 10.54 kg/cm², 17.5 kg/cm², and 21 kg/cm² (Custom up to 32 kg/cm²) |

| Fuel Options | A-Grade Coal, Lignite, Biomass Briquettes, and Wood Logs |

| Design Type | Horizontal 3-Pass Wet Back / Fluidized Bed Combustion (FBC) |

| Efficiency | Up to 82% with Waste Heat Recovery Units |

| Automation | Semi-Automatic to Fully PLC Controlled Systems |

Why Choose Our Coal Fired Boilers?

- Proven Durability: Built with high-grade seamless tubes and heavy-duty shells designed to withstand the rigors of continuous industrial use.

- Lower Operating Costs: Coal remains one of the most affordable fuels for high-capacity steam generation; our optimized air-to-fuel ratio ensures you get the most energy out of every kilogram.

- Safety First: Equipped with dual safety valves, high-pressure cut-offs, and advanced water-level controllers to prevent dry firing and over-pressurization.

- Rapid Payback: The combination of low fuel costs and high efficiency ensures a fast Return on Investment (ROI) compared to oil or gas-fired systems.

Core Industry Applications

Our heavy-duty coal-fired systems are the backbone of various large-scale manufacturing sectors:

- Textile Processing: Reliable steam for high-volume dyeing, drying, and stenters.

- Chemical & Pharma: Consistent process heat for reactors and large-scale sterilization.

- Paper & Pulp: Sustained high-pressure steam for drying and finishing cycles.

- Distilleries: Efficient thermal energy for fermentation and distillation processes.

- Plywood & Laminates: Delivering the consistent temperature required for critical hot-press cycles.