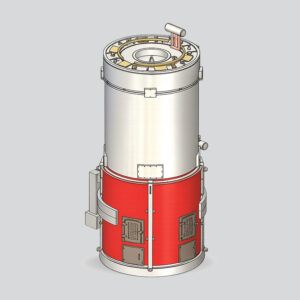

Briquette Fired Boilers: Sustainable & Cost-Effective Industrial Steam Solutions

At IndianBoilers.com, we specialize in high-performance Briquette Fired Boilers that allow industries to transition from expensive fossil fuels to sustainable biomass energy. Our boilers are specifically engineered to utilize Biomass Briquettes (White Coal), which provide uniform combustion, high calorific value, and minimal ash content. By switching to our briquette-fired systems, industrial units can reduce their operational fuel costs by up to 50% while achieving carbon-neutral production goals.

Key Features & Performance

- High Thermal Efficiency: Our precision-engineered three-pass design, coupled with integrated heat recovery units (Economizers/APH), ensures thermal efficiency of up to 82% ± 2%.

- Multi-Fuel Versatility: While optimized for biomass briquettes, the robust grate system can also efficiently burn Wood Logs, Coal, and Pellets, ensuring fuel security year-round.

- Optimized Combustion Chamber: Features a large furnace volume and specialized grate design to handle the high-density nature of briquettes, ensuring complete combustion and steady steam pressure.

- Automated Feeding Systems: Available with screw-feeders or pneumatic feeding systems to minimize manual intervention and maintain a constant fuel-to-air ratio.

- IBR Certified Safety: Manufactured under strict Indian Boiler Regulations (IBR) using high-grade SA 515/516 boiler-quality steel and seamless tubes for 20+ years of service life.

Technical Specifications

| Specification | Details |

| Capacity Range | 0.5 TPH to 15.0 TPH |

| Working Pressure | 10.54 kg/cm² to 21 kg/cm² (Customizable up to 32 kg/cm²) |

| Fuel Compatibility | Biomass Briquettes, Wood Chips, Mustard Husk, and Coal |

| Boiler Type | Horizontal Three-Pass / Hybrid (Water Wall + Smoke Tube) |

| Efficiency | 78% to 82% (with Heat Recovery Units) |

| Automation Grade | Semi-Automatic / Fully Automatic |

Why Switch to Briquette Fired Boilers?

- Major Fuel Cost Savings: Biomass briquettes are significantly cheaper than Diesel (LDO), Furnace Oil (FO), or Gas, offering a payback period of often less than 12-18 months.

- Eco-Friendly & Carbon Neutral: Briquettes are made from agricultural waste (Groundnut shells, Rice husk, Sawdust). Burning them is considered carbon-neutral, helping your plant meet ESG and pollution board (CPCB) norms.

- Uniform Heating: Unlike loose wood, briquettes have a consistent moisture content and density, leading to more predictable steam generation and easier boiler operation.

- Clean Emissions: Integrated with Multi-cyclone Dust Collectors (MDC) or Bag Filters, our systems ensure that particulate matter remains well within permissible environmental limits.

Core Industry Applications

Our briquette-fired steam systems are a reliable “Green Heart” for various industrial clusters:

- Textiles: Reliable steam for high-temperature dyeing, printing, and finishing processes.

- Food & Dairy: Sustainable thermal energy for pasteurization, drying, and sterilization.

- Pharmaceuticals & Chemicals: Precise process heating for reactors and distillation columns.

- Plywood & Laminates: Cost-effective steam for hot presses and drying chambers.

Ready to Reduce Your Fuel Bills?

Contact our engineering team at Ahmedabad for a customized quote and fuel-saving analysis.