-

Industrial Boiler

1000 Kg – 1 Ton Horizontal Fire Tube Boiler (Wood Log Fuel)

₹1,553,000.00 Add to cart -

Industrial Boiler

1500 Kg – 1.5 Ton Steam Boiler (Groundnut Fired) – Biomass Industrial

₹1,650,000.00 Add to cart -

Industrial Boiler

2000 Kg – 2 Ton Wood Pellet Fired Fire Tube Steam Boiler

₹2,660,000.00 Add to cart -

Industrial Boiler

3000 Kg – 3 Ton Bagasse Fired Boiler – Automatic Biomass Steam Generator

₹3,150,000.00 Add to cart -

Industrial Boiler

5000 Kg – 5 Ton Coal Fired Steam Boiler – Industrial Horizontal Steam Generator

₹5,000,000.00 Add to cart -

Industrial Boiler

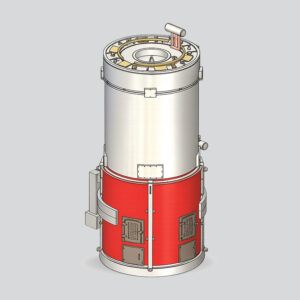

High Pressure Industrial Steam Boiler 750 Kg/hr – Heavy Duty Boiler

₹1,380,000.00 Add to cart

High-Efficiency Waste-to-Energy Solutions for Sugar Mills, Distilleries, and Paper Industries.

At IndianBoilers.com, we engineer advanced Bagasse Fired Boilers designed to transform agricultural residue into a powerful energy asset. Recognizing that bagasse is a primary byproduct of the sugar industry, our boilers are optimized to handle its unique characteristics—high moisture content and fibrous texture—ensuring stable, high-pressure steam generation while significantly reducing your carbon footprint and fuel costs.

Key Features & Performance

- High Thermal Efficiency: Featuring a precision-engineered 3-pass design and integrated heat recovery units (Economizers/APH) that push thermal efficiency to 82% and above.

- Large Combustion Furnace: Specifically designed with a generous furnace volume to accommodate the high-volume nature of bagasse, ensuring complete combustion and minimal ash carryover.

- Advanced Fuel Feeding: Available with automated pneumatic or mechanical feeding systems for a steady fuel supply and uniform steam pressure.

- Robust Grate System: Equipped with specialized stationary, dumping, or travelling grates designed to manage the high silica and ash content inherent in bagasse.

- IBR Compliant Safety: Fully manufactured under Indian Boiler Regulations (IBR) using premium SA 515/516 Gr. 70 boiler-quality plates for maximum longevity.

Technical Specifications

| Specification | Details |

| Capacity Range | 1.0 TPH to 20.0 TPH |

| Working Pressure | 10.54 kg/cm² to 32 kg/cm² |

| Fuel Type | Sugarcane Bagasse, Pith, Wood Waste, and Multi-fuel options |

| Automation | Fully Automatic / Semi-Automatic |

| Temperature | Saturated Steam or Superheated (up to 400°C for Turbine use) |

| Efficiency | 80% ± 2% (with Heat Recovery Units) |

Why Choose Our Bagasse Boilers?

- Fuel Cost Savings: Switching from fossil fuels to bagasse can reduce direct fuel costs by up to 80-90%, depending on onsite availability.

- Sustainable & Carbon Neutral: Bagasse is a renewable biomass source. Burning it for energy completes a carbon-neutral cycle, helping your facility meet ESG goals.

- Built for Durability: We utilize high-grade seamless tubes and superior metallurgy to resist the corrosive elements often found in biomass flue gases.

- Integrated Pollution Control: Every unit is supplied with high-efficiency Multi-cyclone Dust Collectors (MDC) or Bag Filters to comply with stringent environmental norms.

Core Industry Applications

Our bagasse-fired systems are the “Gold Standard” for industries looking for circular economy solutions:

- Sugar Mills: Direct utilization of mill-wet bagasse for process steam and power.

- Distilleries: Reliable steam for fermentation and distillation processes.

- Pulp & Paper: Cost-effective thermal energy for drying and chemical recovery.

- Food Processing: Sustainable steam for sterilization and dehydration.