The Hot Water Boiler is the core of many building heating systems around the world. Unlike its powerful cousin, the steam boiler, its job is simply to heat water to a high temperature, not to boil it into high-pressure vapor.

1. What Does a Hot Water Boiler Do?

A hot water boiler operates on a very simple, two-part principle:

- Heating the Water: Fuel (usually natural gas, oil, or electricity) is burned inside the boiler’s combustion chamber. This heat is transferred to water circulating inside a heat exchanger.

- Circulating the Heat: A pump pushes the hot water out of the boiler and through a closed-loop system of pipes to the rest of the building.

The water is used to provide space heating for buildings and, sometimes, to provide domestic hot water (the water you use in sinks and showers).

2. How Hot Water Heats Your Space

The circulating hot water delivers heat using one of three common methods:

- Radiators: The hot water flows into metal radiators, which radiate heat into the room.

- Baseboard Heaters: Similar to radiators, these metal units run along the floor to distribute heat evenly.

- Hydronic Radiant Floors: The hot water runs through tubes embedded in the floor, turning the entire floor into a gentle, efficient heater.

Once the water has given up its heat, it returns to the boiler to be reheated, creating a continuous, efficient cycle.

3. Key Types of Hot Water Boilers

Hot water boilers are generally categorized by the temperature and pressure at which they operate. The two primary types used in modern infrastructure include:

- Low-Temperature Hot Water (LTHW)

- Maximum Temperature: Up to 110°C (230°F).

- Common Use: Ideal for Residential and Commercial building heating, such as schools and offices.

- Key Characteristic: It operates at low pressure, which significantly minimizes safety complexity and maintenance requirements.

- High-Temperature Hot Water (HTHW)

- Maximum Temperature: Above 121°C (250°F).

- Common Use: Utilized for District Heating (warming entire campuses or neighborhoods) and large-scale industrial processes.

- Key Characteristic: It operates at much higher pressures, which is necessary to prevent the water from turning into steam at these elevated temperatures.

4. Condensing vs. Non-Condensing Boilers

For general audiences, the most important distinction is efficiency:

- Non-Condensing (Traditional) Boiler: Heat is recovered from the fuel, but a lot of heat energy is lost up the chimney (flue) with the exhaust gases.

- Condensing (High-Efficiency) Boiler: These units are designed to capture the heat that would normally be wasted. They cool the exhaust gases so much that the water vapor in the gas turns back into liquid water (condenses). This condensation process releases extra heat, which is then used to preheat the incoming water.

- The result? Condensing boilers can be 20% to 30% more efficient than older models, leading to significant energy savings.

Why is this important?

Hot water boilers are the foundation of comfortable living and working in cold climates. By using water to move heat around a building, they offer a reliable, quiet, and highly controllable heating solution that has been a standard for over a century.

Frequently Asked Questions

What are the common temperature ranges?

- Low Temperature: Up to 95°C (usually non-pressurized).

- Medium Temperature: 95°C to 120°C.

- High Temperature (HTHW): Above 120°C (requires pressurized systems to prevent boiling).

What is the difference between a Hot Water Boiler and a Steam Boiler?

The main difference is the phase of the medium. Steam boilers provide "Latent Heat" (very high energy for sterilization or power), while hot water boilers provide "Sensible Heat." Hot water systems are generally more efficient for simple heating because they avoid the energy losses associated with steam traps and blowdowns.

What fuels can be used in your Hot Water Boilers?

At indianboilers.com, we offer multi-fuel flexibility:

- Solid Fuels: Wood, Briquettes, Coal, Rice Husk.

- Liquid/Gas: Diesel (HSD), LDO, Natural Gas, LPG.

- Electric: Zero-emission heating elements.

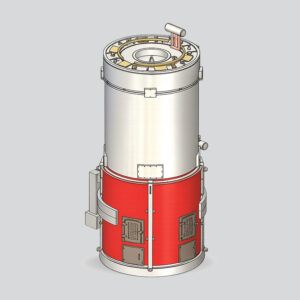

Are these boilers "Shell Type" or "Coil Type"?

We manufacture both. Shell Type boilers offer a large water hold-up and are great for fluctuating loads. Coil Type (Instantaneous) boilers are compact and provide hot water within minutes of start-up.

How is the temperature controlled?

Our boilers use a Digital Temperature Controller or PLC system that modulates the burner or fuel feeder. Once the water reaches the set-point, the system automatically slows down or shuts off, ensuring fuel efficiency.

Why is a circulating pump necessary?

Because hot water systems rely on "Forced Circulation," a pump is required to push the water through the heat exchangers and return it to the boiler. This prevents localized boiling and ensures uniform heating across your facility.

Do I need to treat the water for a hot water boiler?

Yes. Even though it's a closed loop, "Hard Water" will cause Limescale buildup on the heating surfaces. Just 1mm of scale can reduce efficiency by 10% and eventually lead to tube failure. A standard water softener is highly recommended.

What is the typical thermal efficiency?

Most of our modern oil/gas hot water boilers operate at 88% to 92% efficiency. Solid fuel models typically range between 78% and 82%.

How can I increase the efficiency of my system?

Installing an Economizer or a Waste Heat Recovery Unit (WHRU) on the flue gas outlet can increase efficiency by pre-heating the return water using "waste" heat.

Does a Hot Water Boiler require IBR (Indian Boiler Regulations) registration?

In India, if the water temperature stays below 100°C, the equipment is generally classified as a "Hot Water Generator" and does not require IBR registration. However, if it exceeds 100°C, it must be registered under the Boilers Act, 1923.

What are the advantages of a "Non-IBR" Hot Water Boiler?

- No annual government inspections.

- No need for a certified boiler attendant (saving on labor costs).

- Lower initial administrative costs and faster installation.

What happens if the water overheats?

Our boilers are equipped with an Over-Temperature Cut-off. If the temperature exceeds the safe limit, the system automatically kills the flame/power. We also install Pressure Relief Valves (PRV) as a secondary safety measure.

What is a "Slow Drain Test"?

This is a maintenance procedure where the water is slowly drained to ensure the Low Water Level Cut-off correctly shuts down the burner, preventing the boiler from "dry firing."

What is the price of an Industrial Hot Water Boiler?

Prices depend heavily on the capacity (kcal/hr) and fuel type. For 2025, approximate rates at indianboilers.com are:

- Small (50k - 2 Lac kcal/hr): ₹1.5 Lakh – ₹4 Lakh.

- Medium (5 Lac - 10 Lac kcal/hr): ₹6 Lakh – ₹12 Lakh.

- Large (20 Lac+ kcal/hr): ₹20 Lakh+.

Which fuel is the most cost-effective?

Biomass (Wood/Briquettes) offers the lowest running cost in India. However, Gas/Oil boilers have a lower initial footprint and require zero manual labor, making them better for urban industries.

What factors most affect the final quote?

- Fuel Type: Gas burners are more expensive than manual solid-fuel grates.

- Material: Stainless steel (for clean water) costs more than carbon steel.

- Automation: PLC-based touchscreens add to the cost but improve ROI.

What is the typical ROI period?

When switching from an inefficient electric heater to a Biomass or Gas Hot Water Boiler, most industrial clients see a full return on investment (ROI) within 8 to 14 months.

How often should the boiler be serviced?

We recommend a monthly visual inspection and a deep service every 6 months. This includes cleaning the burner, checking the pump seals, and flushing any sediment from the bottom of the tank.

How do I get a quote from indianboilers.com?

Simply visit our website and provide your required LPH (Liters Per Hour) and the Desired Temperature. Our engineers will provide a custom technical and commercial proposal within 24 hours.